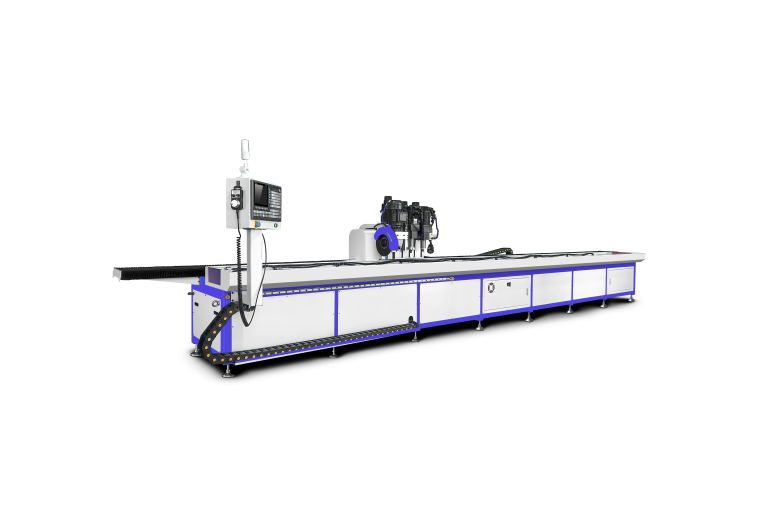

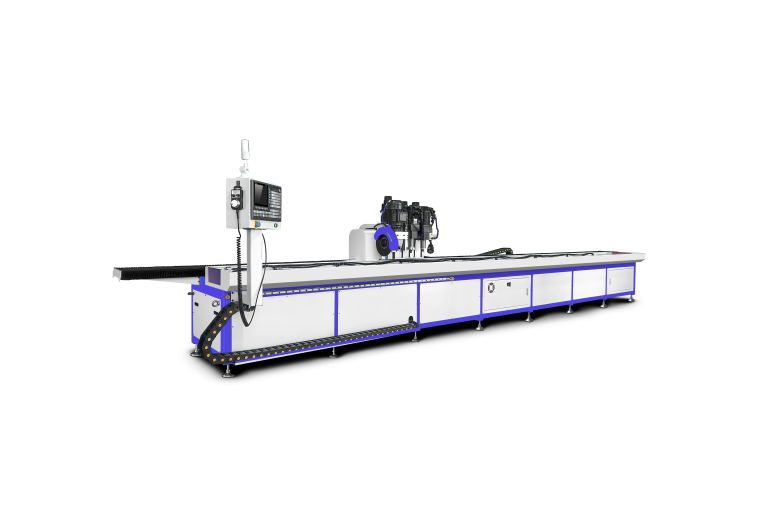

Aluminium Profile Drilling Tapping Cutting Tool

페이지 정보

본문

This eliminates hands-on dimension and positioning mistakes, making certain constant outcomes throughout sets. ** Automatic Procedure and Easy Shows **.

With its intelligent control system, the driver can quickly input machining specifications such as opening position, tapping depth, and reducing length. It integrates 3 important machining procedures-- ** piercing **, ** touching **, and ** reducing **-- right into a solitary system, enabling suppliers to complete facility construction jobs effectively and accurately.

** High Precision and Stability **.

Furnished with precision guide rails and servo motors, the equipment delivers outstanding machining precision.

The inflexible body framework reduces resonance, making sure tidy holes, exact threads, and smooth cutting sides.

This saves both time and manufacturing facility space, making it excellent for contemporary aluminium handling workshops. ** Appropriate for Lengthy Aluminium Profiles **.

The equipment can refine lengthy or extra-large aluminium profiles with high accuracy.

It integrates three crucial machining operations-- ** piercing **, ** touching **, and ** reducing **-- into a single device, allowing suppliers to full facility manufacture jobs successfully and accurately.

The equipment runs via a combination of mechanical motion and CNC or electronic control. An ** aluminium profile drilling touching cutting equipment ** is a high-performance and multifunctional piece of tools designed for precision handling of aluminium profiles. Automatic placing and device motion ensure consistent high quality and minimize human error.

** Resilience and Low Upkeep **.

Designed for long-lasting commercial usage, the equipment's elements are made from high-strength products and treated for wear resistance.

A ** CNC-controlled version ** offers the highest possible level of precision and productivity.

An ** aluminium profile boring tapping reducing equipment ** is a high-performance and multifunctional piece of tools designed for accuracy handling of aluminium profiles. With a ** Moxisys ** machine, manufacturers can accomplish exceptional accuracy, regular outcomes, and better performance while reducing operational costs.

** Smooth and Burr-Free Cutting **.

The reducing system uses high-speed carbide saw blades and effective air conditioning to create tidy, burr-free edges.

Relying on the design, it might include ** manual, semi-automatic, or fully automated ** control systems. ** Multifunctional Layout **.

The maker incorporates exploration, tapping, and reducing right into one system, minimizing the demand for multiple configurations or equipment.

Its solid structure, progressed control, and smooth performance make it suitable for both tiny workshops and large production plants.

By integrating 3 significant machining procedures right into one system, it simplifies operations, boosts accuracy, and saves important time.

Aluminium profiles are firmly secured onto the worktable, and the maker executes automated exploration, tapping, and cutting according to the configured specifications.

Routine lubrication and very little maintenance maintain it performing successfully over several years.

* ** High rigidness framework ** for vibration-free procedure.

* ** Powerful spindle motors ** for fast exploration and tapping.

* ** Intelligent CNC system ** for simple operation and automation.

* ** Energy-efficient layout ** with reduced sound and decreased power intake.

* ** Comprehensive after-sales support **, including setup, training, and extra components service.

Some designs are furnished with automated feeding and positioning systems for continual production and very little product waste.

Depending on the version, it may include ** guidebook, semi-automatic, or fully automatic ** control systems.

Whether you're creating aluminium doors and home windows, curtain wall surfaces, or industrial elements, this equipment offers the efficiency, integrity, and effectiveness required to stay affordable in the modern-day aluminium handling market.

This is especially important for aluminium window and door profiles where visual quality and assembly accuracy matter.

* ** High-speed pin motor ** for tidy and specific boring and tapping.

* ** Accuracy direct overview rails ** and sphere screws for smooth motion and long-lasting accuracy.

* ** Servo-driven feeding system ** for stable cutting performance.

* ** Sturdy device structure ** for rigidness and vibration-free operation.

* ** Lubrication and cooling system ** to extend tool life and preserve tidy cuts.

Operators can input machining data directly into the control system or import CAD/CAM documents for automatic production.

This sort of machine is extensively made use of in the manufacturing of ** aluminium home windows, doors, drape wall surfaces, solar frameworks, and industrial elements **, where specific machining and clean finishes are essential. The ** aluminium profile exploration touching reducing equipment ** is a vital tool in the aluminium corner brace bracket drilling tapping cutting machine construction sector.

With its intelligent control system, the driver can quickly input machining specifications such as opening position, tapping depth, and reducing length. It integrates 3 important machining procedures-- ** piercing **, ** touching **, and ** reducing **-- right into a solitary system, enabling suppliers to complete facility construction jobs effectively and accurately.

** High Precision and Stability **.

Furnished with precision guide rails and servo motors, the equipment delivers outstanding machining precision.

The inflexible body framework reduces resonance, making sure tidy holes, exact threads, and smooth cutting sides.

This saves both time and manufacturing facility space, making it excellent for contemporary aluminium handling workshops. ** Appropriate for Lengthy Aluminium Profiles **.

The equipment can refine lengthy or extra-large aluminium profiles with high accuracy.

It integrates three crucial machining operations-- ** piercing **, ** touching **, and ** reducing **-- into a single device, allowing suppliers to full facility manufacture jobs successfully and accurately.

The equipment runs via a combination of mechanical motion and CNC or electronic control. An ** aluminium profile drilling touching cutting equipment ** is a high-performance and multifunctional piece of tools designed for precision handling of aluminium profiles. Automatic placing and device motion ensure consistent high quality and minimize human error.

** Resilience and Low Upkeep **.

Designed for long-lasting commercial usage, the equipment's elements are made from high-strength products and treated for wear resistance.

A ** CNC-controlled version ** offers the highest possible level of precision and productivity.

An ** aluminium profile boring tapping reducing equipment ** is a high-performance and multifunctional piece of tools designed for accuracy handling of aluminium profiles. With a ** Moxisys ** machine, manufacturers can accomplish exceptional accuracy, regular outcomes, and better performance while reducing operational costs.

** Smooth and Burr-Free Cutting **.

The reducing system uses high-speed carbide saw blades and effective air conditioning to create tidy, burr-free edges.

Relying on the design, it might include ** manual, semi-automatic, or fully automated ** control systems. ** Multifunctional Layout **.

The maker incorporates exploration, tapping, and reducing right into one system, minimizing the demand for multiple configurations or equipment.

Its solid structure, progressed control, and smooth performance make it suitable for both tiny workshops and large production plants.

By integrating 3 significant machining procedures right into one system, it simplifies operations, boosts accuracy, and saves important time.

Aluminium profiles are firmly secured onto the worktable, and the maker executes automated exploration, tapping, and cutting according to the configured specifications.

Routine lubrication and very little maintenance maintain it performing successfully over several years.

* ** High rigidness framework ** for vibration-free procedure.

* ** Powerful spindle motors ** for fast exploration and tapping.

* ** Intelligent CNC system ** for simple operation and automation.

* ** Energy-efficient layout ** with reduced sound and decreased power intake.

* ** Comprehensive after-sales support **, including setup, training, and extra components service.

Some designs are furnished with automated feeding and positioning systems for continual production and very little product waste.

Depending on the version, it may include ** guidebook, semi-automatic, or fully automatic ** control systems.

Whether you're creating aluminium doors and home windows, curtain wall surfaces, or industrial elements, this equipment offers the efficiency, integrity, and effectiveness required to stay affordable in the modern-day aluminium handling market.

This is especially important for aluminium window and door profiles where visual quality and assembly accuracy matter.

* ** High-speed pin motor ** for tidy and specific boring and tapping.

* ** Accuracy direct overview rails ** and sphere screws for smooth motion and long-lasting accuracy.

* ** Servo-driven feeding system ** for stable cutting performance.

* ** Sturdy device structure ** for rigidness and vibration-free operation.

* ** Lubrication and cooling system ** to extend tool life and preserve tidy cuts.

Operators can input machining data directly into the control system or import CAD/CAM documents for automatic production.

This sort of machine is extensively made use of in the manufacturing of ** aluminium home windows, doors, drape wall surfaces, solar frameworks, and industrial elements **, where specific machining and clean finishes are essential. The ** aluminium profile exploration touching reducing equipment ** is a vital tool in the aluminium corner brace bracket drilling tapping cutting machine construction sector.

- 이전글Play m98 Casino site Online in Thailand 25.10.28

- 다음글Ufabet: Enjoy Thrilling Gambling Establishment Gamings in Thailand 25.10.28

댓글목록

등록된 댓글이 없습니다.